Our Process Starts with Precision

What Powers Our Precision

-

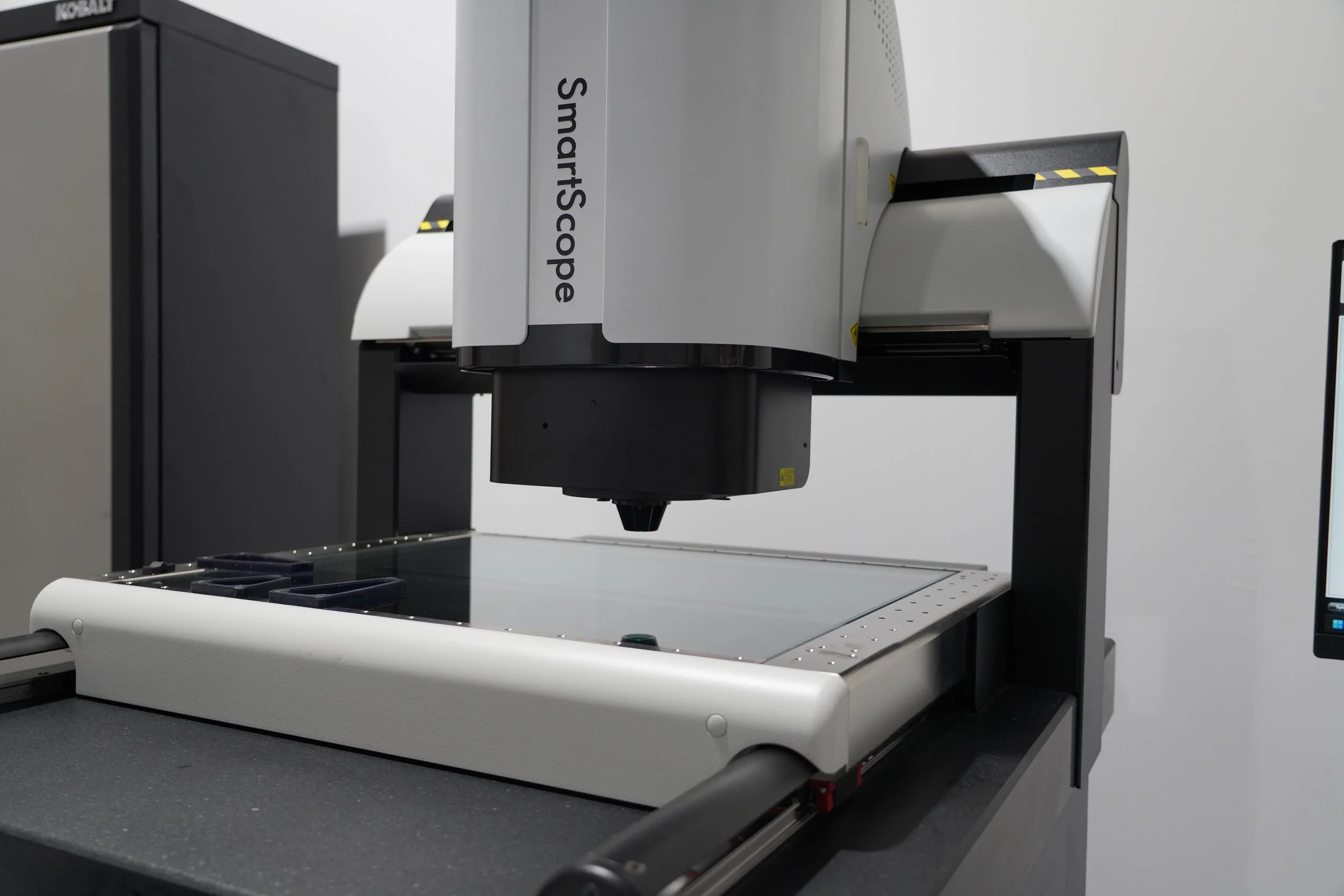

OGP G45 SmartScope

This multisensor measurement system allows non-contact inspection down to the micron level. It ensures dimensional conformity of critical features, validating both tooling and molded parts with unmatched accuracy.

-

Sub-Micron 5-Axis Mill

This high-precision milling center enables us to machine complex geometries and mirror-finish cavities with sub-micron accuracy. Perfect for micro mold components, optical surfaces, and high-performance tooling inserts.

-

Micro Injection Molding Machine

Engineered for precision, the Sodick LP20EH3 features a V-Line® plunger system that separates plasticizing and injection, eliminating backflow and ensuring consistent shot-to-shot accuracy. Ideal for producing medical, electronic, and microfluidic components with ultra-tight tolerances.

-

ERP System

Our custom Fusion Operations ERP system ties together design, tooling, molding, and inspection. It provides real-time traceability, streamlined scheduling, and complete process control — giving us the agility to turn around high-precision projects faster than anyone else in the industry.

-

CAD & Simulation

We rely on SolidWorks and Fusion to design, simulate, and optimize micro-scale components and tooling. This software foundation enables rapid iteration, precision modeling, and seamless transition from concept to cut — ensuring parts are designed for manufacturability from the start.